Atra Plastics Inc. operates a state-of-the-art facility on a 3+ acre site, featuring a 30,000 sq. ft. production shop and a 7,000 sq. ft. office space. Specializing in thermoforming and injection molding of decorative trim products, the facility is IATF 16949 certified, ensuring the highest quality standards. Atra is gradually expanding the production capacity of its Michigan factory and has open capacity for future growth, with plans to construct additional space to meet evolving production demands.

Atra Plastics’ engineering team provides comprehensive support in part review, tooling design, CAE analysis, and CNC manufacturing, while also leading or assisting with R&D projects involving new materials, processes, and technologies. Our in-house capabilities include developing prototype and production thermoform tools and trim dies, as well as utilizing laser scanning technology for precise dimensional analysis.

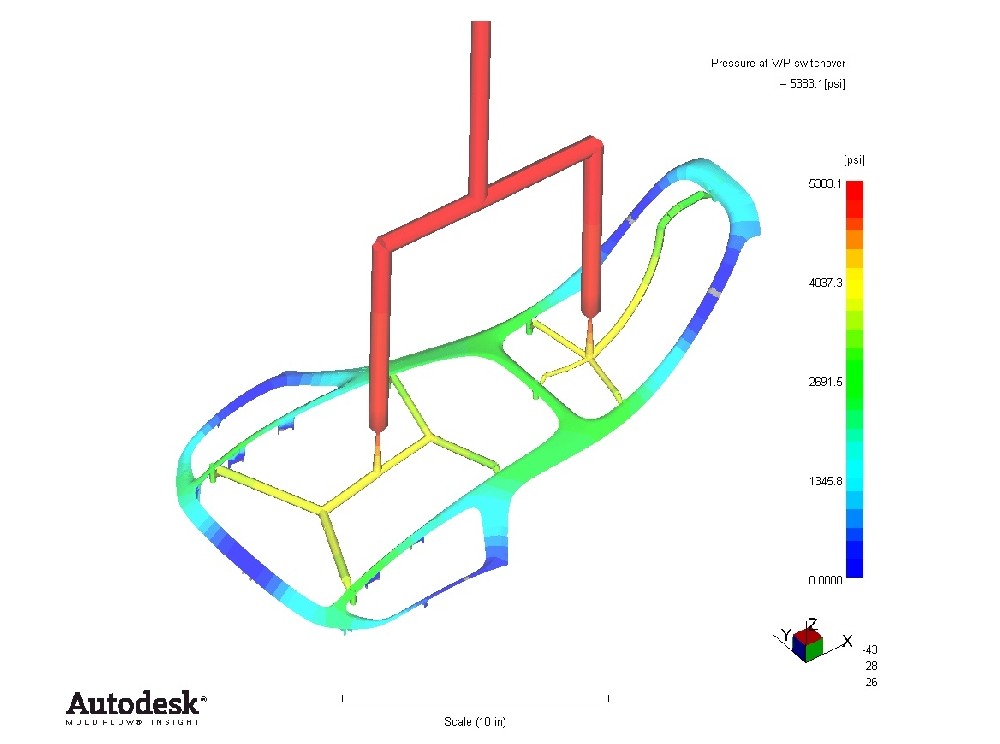

Atra Plastics leverages advanced technology to meet our customers' injection molding and in-mold decorating (IMD) needs efficiently and cost-effectively. Our molding machines, with clamping capacities from 280 to 1,400 tons, provide the flexibility to handle diverse project requirements.